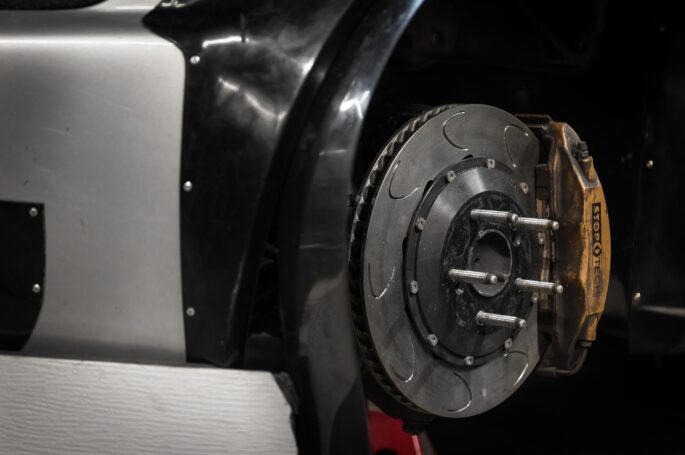

Brakes are the most essential system in your race car. The consequences of being unable to stop can take a fun day at the track and turn it expensive or even deadly in the blink of an eye. In this article, I will explore the basics of how disc brakes work. I’ll use my time … Continue reading Nerd Talk: Brakes Part 1